Optimise your system with an Oil/Water Separator

Published date: 21 May 2024

Avoid costly fines, protect the environment and optimise your compressed air system.

When it comes to manufacturing, it is imperative to ensure that environmental impact is mitigated as much as possible.

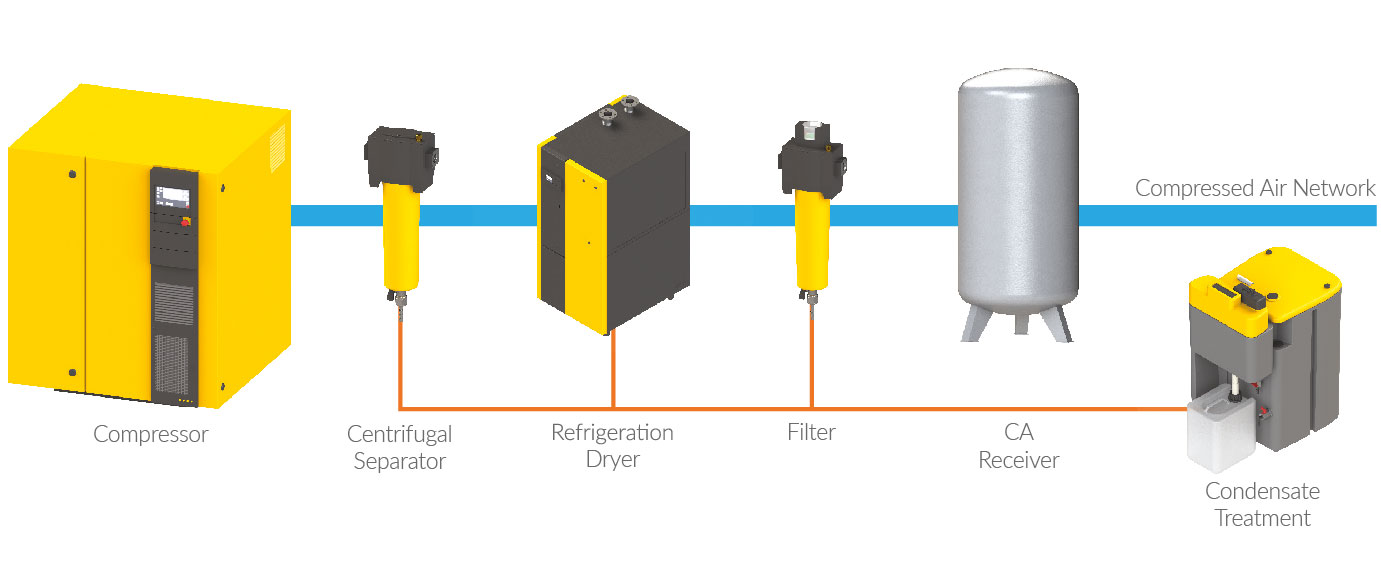

Often, contaminants such as oil can end up in the water cycle, leading to a plethora of issues that can last for decades. In compressed air, trace amounts of oil can be found in condensate from lubricated air compressors. Therefore, preventing this contaminated condensate from being discarded irresponsibly is crucial. AEP can offer a range of Oil/Water Separators to efficiently separate oil and other contaminants from water, ensuring compliance with environmental regulations and helping you to implement sustainable business practices.

Key features of our range include:

- High Efficiency Separation – Achieve purity levels that meet or exceed regulatory standards

- Compact and Space-Saving – Suitable for installations with limited space

- Compliance Assurance – Avoid unnecessary fines and meet your company's environmental goals

- Simple Operation – User-friendly controls and automation options, requiring minimal operator intervention

- Low Maintenance – Reduce downtime and see long-term cost savings

- Robust Construction – Withstand the demands of industrial applications and harsh environmental conditions

It is not simply an environmental good deed, but across the world it is required by law. In 1991, the UK introduced the Water Resources Act, making it an offence to knowingly allow toxic waste to enter surface or ground water.

Failure to comply with this law comes with a maximum fine of £20,000.

With such potentially severe costs to both your business and the environment, it is important that you invest in your infrastructure to prevent a costly hit to your wallet, and contribute to a more sustainable and ecologically friendly industrial landscape.